|

|

FT

8570217

Maj.2 : 20.06.16 |

PDF

|

|

|

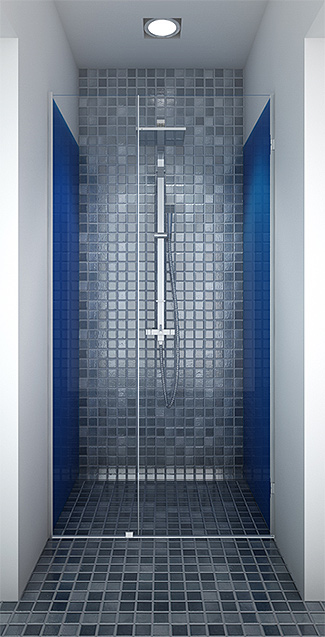

FT844 Shower by Capsi

|

|

FT842 Showcase by Adler (fr)

|

|

FT839 Adslide

|

|

|

FT860 aluminium profiles by Adler VF

|

|

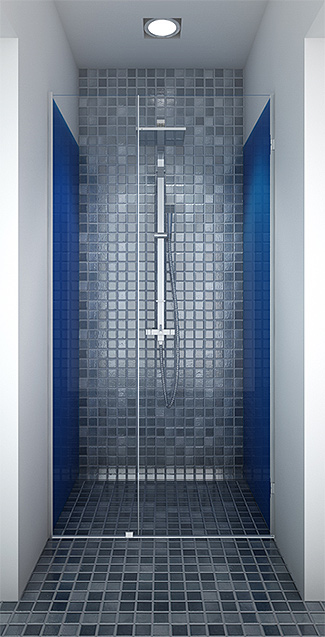

FT855 Shower Walk-in

|

|

FT853 Shower Adler VF

|

|

FT849 Shower by Adler

|

|

|

Catalogue hinges and hardware

for glass enclosures :

shower, doors...

|

|

|

|

|

|

Working in partnership with Saint-Gobain Glassolutions, Adler SAS has developed Clip-In Door®, a hinge that can be used to create glass doors of unrivalled transparency. A full range of Adler accessories available from stock for use in the straightforward installation of a wide variety of shower screens, on walls that are often less than perfect, uneven and out of plumb, with a swing door that closes by means of the pressure of a seal against a fixed glass panel. This seal itself has been specially developed to meet the miniaturisation and transparency requirements of Clip-In Door and also provides effective protection for the free edge of the door or the fixed panel. |

|

|

| Single door in an alcove. |

Door and fixed panel less than 35 cm wide in an alcove. |

|

|

| Corner cubicle with wall-hung door and a fixed return less than 35 cm wide. |

Corner cubicle with wall-hung door and a fixed return in excess of 35 cm wide, stabilised with a square support bar. |

|

|

| Corner cubicle with wall-hung door, fixed in-line panel and fixed return screwed to the edge of the fixed in-line panel: fixed in-line panel less than 35 cm wide. |

Corner cubicle with wall-hung door, fixed in-line panel and fixed return inserted into double-edged section. |

|

|

| Corner cubicle with door hung on fixed return: open-joint structure. |

Corner cubicle with door hung on fixed return: watertight structure. |

|

|

’Other Clip-In Door shower screen models can also be created, such as, for example: (a) a corner model with a door hung on the fixed return and a fixed in-line panel abutting the wall; (b) against a wall, with a door hung on one of the returns, a fixed in-line panel bracing the other fixed return and a support bar connecting the two return panels; (c) as with Capsi, if one of the fixed returns is very narrow (less than 350 mm wide here, as the glass is 10 mm thick), it makes it possible to construct a cubicle with a single in-line door, mounted on either the larger or the smaller return.

All screens designed to be produced in non-toughened laminated 55.2 glass (see FT-8521114) are of course suitable for use with the Clip-In Door hinge instead of the Adler VF hinge. Compared with the models described here, these offer the particular advantage of reduced glass shaping costs, significant installation tolerance and correction via the build process of tempering defects (distortion of the glass, etc.) which may adversely affect the more lightweight structures also shown here.

NB: in the diagrams below, the Adler product numbers are indicative and correspond by default to products with a brushed stainless steel finish. Also available in high shine chrome plate. |

| Model CI-1: Single door in an alcove |

|

|

With Clip-In Door, this installation offers a simple, fully watertight single door solution for any alcove, even where walls are out-of-plumb or uneven. The wall sections compensate efficiently for all imperfections of this kind. They are also the only effective solution for ensuring that a tiled wall is watertight, particularly around the tile joints. The supporting section for the hinge must be glued and then screwed into a vertical position. Ideally, the section for the free edge of the door should be fitted after the door is hung, to ensure the required clearance of 2 mm up the full height of the door. |

|

|

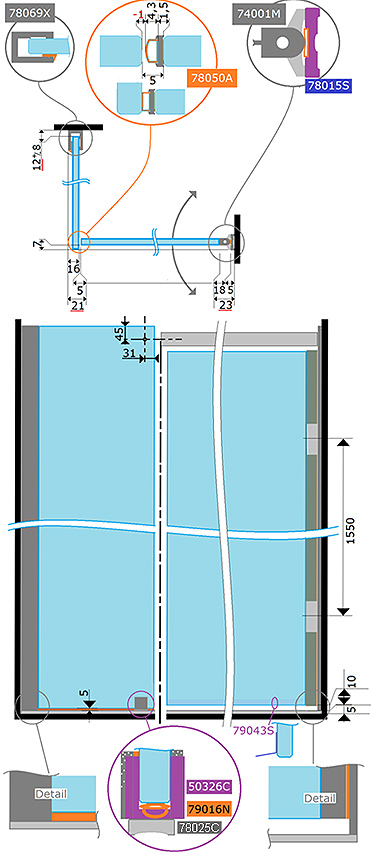

| Model CI-2: Door and

fixed panel less than 35 cm wide in an alcove |

|

|

With Clip-In Door, this alcove installation with a fixed glass panel and wall-mounted hinged door offers a simple, fully watertight solution. The wall sections are an efficient way to compensate for out-of-plumb and uneven wall surfaces. They are also the only effective solution for ensuring that a tiled wall is watertight, particularly around the tile joints. The supporting section for the hinge must be glued and then screwed into a vertical position. The U section for the fixed glass panel allows for adjustment by +/-8 mm, which is sufficient in the majority of cases. The front of the U section is 27 mm wide; the Clip-In Door hinge and associated flat section together measure 23 mm, providing an elegant overall balance.

|

|

|

| Model CI-3: Corner screen with wall-hung door and a fixed return less than 35 cm wide |

With Clip-In Door, where the fixed glass return panel is sufficiently narrow (less than 35 cm wide), this corner and partial alcove installation offers high transparency and simplicity and is fully watertight. On the in-line panel side, the flat section against the wall behind the hinge naturally compensates for uneven or out-of-plumb wall surfaces. It also contains the seal that keeps the hinge watertight. On the fixed return side, the U section glued and screwed to the wall allows for adjustment of the installation by +/-8 mm. The front of the U section is 27 mm wide; the Clip-In Door hinge and associated flat section together measure 23 mm, providing an elegantly balanced installation. Assembly is entirely mechanical, and the only seal strip, in the U section on the return panel, is slimline and near-invisible and is located on the external face of the cubicle, where it cannot be affected by water, soap, etc. With Clip-In Door, where the fixed glass return panel is sufficiently narrow (less than 35 cm wide), this corner and partial alcove installation offers high transparency and simplicity and is fully watertight. On the in-line panel side, the flat section against the wall behind the hinge naturally compensates for uneven or out-of-plumb wall surfaces. It also contains the seal that keeps the hinge watertight. On the fixed return side, the U section glued and screwed to the wall allows for adjustment of the installation by +/-8 mm. The front of the U section is 27 mm wide; the Clip-In Door hinge and associated flat section together measure 23 mm, providing an elegantly balanced installation. Assembly is entirely mechanical, and the only seal strip, in the U section on the return panel, is slimline and near-invisible and is located on the external face of the cubicle, where it cannot be affected by water, soap, etc. |

|

|

|

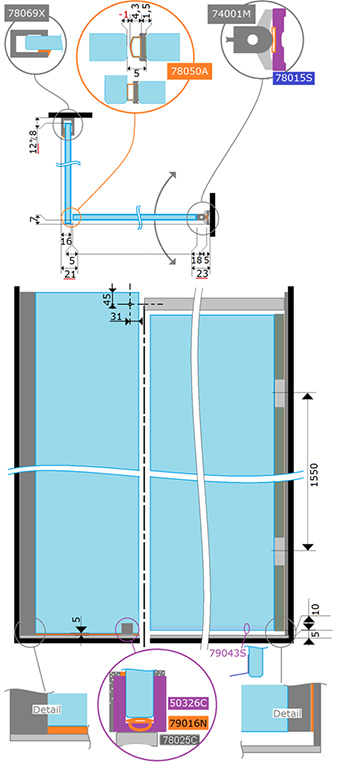

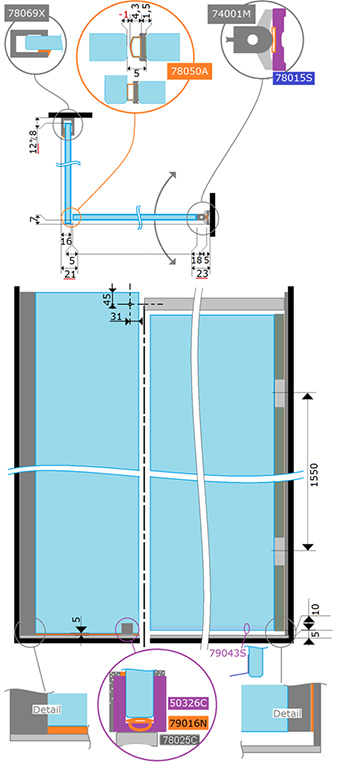

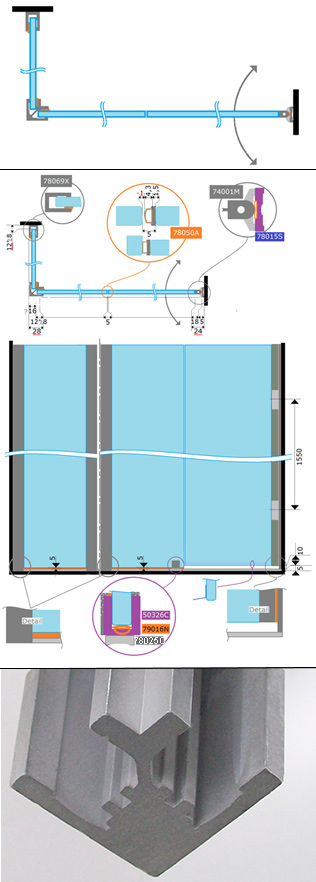

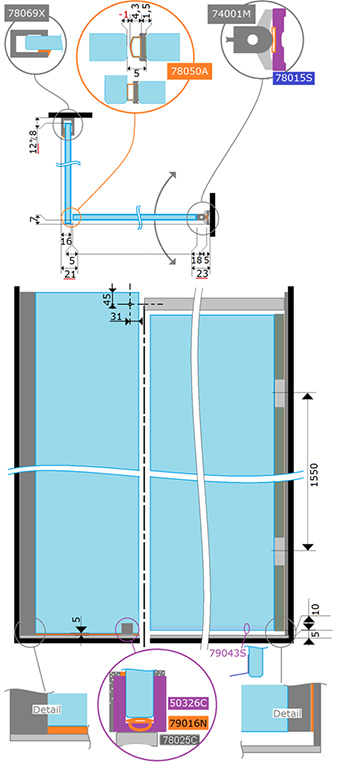

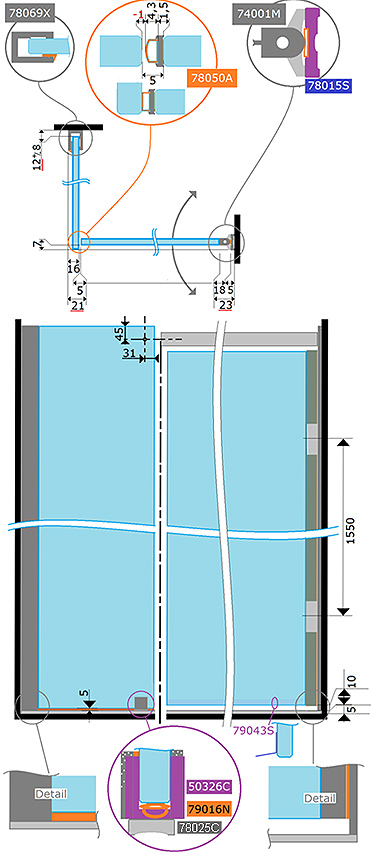

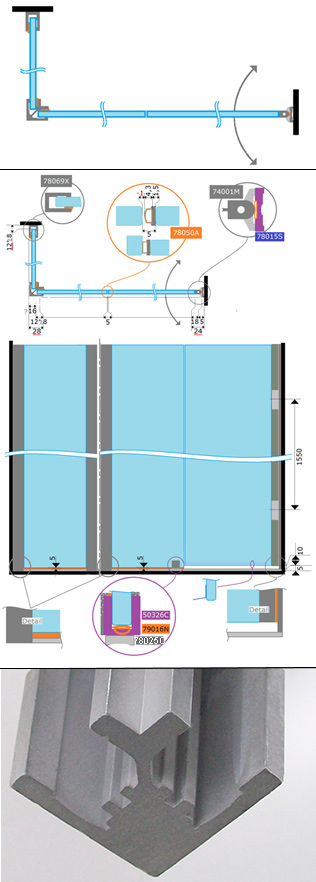

| MModel CI-4: Corner cubicle with wall-hung door and a fixed return in excess of 35 cm wide, stabilised with a square support bar |

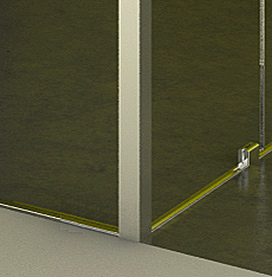

On the fixed return side, the U section recommended for wall mounting helps to compensate for imperfections in the wall surface, providing stability for the installation and simplifying the build process. At the hinge, the flat wall section is essential for secure, easy fitting and a watertight, durable installation. The square 20 x 20 mm support bar provides stability for the in-line panel and maintains the sleek, clean lines of the finish. At floor level, the threshold strips are near invisible, in keeping with the build, and allow the clip that holds the lateral screen in place to be affixed without drilling into the shower tray, with the method of assembly delivering a watertight installation. On the fixed return side, the U section recommended for wall mounting helps to compensate for imperfections in the wall surface, providing stability for the installation and simplifying the build process. At the hinge, the flat wall section is essential for secure, easy fitting and a watertight, durable installation. The square 20 x 20 mm support bar provides stability for the in-line panel and maintains the sleek, clean lines of the finish. At floor level, the threshold strips are near invisible, in keeping with the build, and allow the clip that holds the lateral screen in place to be affixed without drilling into the shower tray, with the method of assembly delivering a watertight installation. |

|

|

|

| Model CI-5: Corner cubicle with wall-hung door, narrow fixed in-line panel and fixed return screwed to the edge of the fixed in-line panel |

On the front of this screen, the inset profile of the fixed glass screen provides visual balance for the combination of the Clip-In Door hinge and associated flat wall section. The distinctive mounting of the inset profile on the fixed return enhances the overall impression of transparency and refinement. This method of installation allows for simple adjustments in the width of both cubicle screens by +/- 8 mm. On the front of this screen, the inset profile of the fixed glass screen provides visual balance for the combination of the Clip-In Door hinge and associated flat wall section. The distinctive mounting of the inset profile on the fixed return enhances the overall impression of transparency and refinement. This method of installation allows for simple adjustments in the width of both cubicle screens by +/- 8 mm. |

|

|

|

| Model CI-6: Corner cubicle with wall-hung door, narrow fixed in-line panel and fixed return inserted into double-edged section |

In this arrangement, the fixed glass panels are all inset, with no screws, making it simple to install and allowing for significant adjustments to size, for example in case of inaccurate measurements. Taken at the scale of a cubicle, all these sections remain slimline and unobtrusive, highlighting the lack of framing on the horizontal edges of the glass panels and making the cubicle look more spaciou In this arrangement, the fixed glass panels are all inset, with no screws, making it simple to install and allowing for significant adjustments to size, for example in case of inaccurate measurements. Taken at the scale of a cubicle, all these sections remain slimline and unobtrusive, highlighting the lack of framing on the horizontal edges of the glass panels and making the cubicle look more spaciou |

|

|

|

Model CI-7: Corner cubicle with door

hung on fixed return: open joint structure |

This screen showcases the full refinement and technical innovation of the Clip-In Door hinge, which is screwed directly to the glass of the fixed return panel at two separate points. The shower frontage is as transparent as possible: a 5 mm-thick flat section at the wall ensures that the free edge of the door fits perfectly so that the cubicle closes properly and is fully watertight at this point; the Clip-In Door hinge forms a slimline, full-height strip 16 mm wide, typically accounting for less than 2% of the width of the door. Without no supporting sections, the point of abutment with the fixed return is no longer fully watertight. This screen showcases the full refinement and technical innovation of the Clip-In Door hinge, which is screwed directly to the glass of the fixed return panel at two separate points. The shower frontage is as transparent as possible: a 5 mm-thick flat section at the wall ensures that the free edge of the door fits perfectly so that the cubicle closes properly and is fully watertight at this point; the Clip-In Door hinge forms a slimline, full-height strip 16 mm wide, typically accounting for less than 2% of the width of the door. Without no supporting sections, the point of abutment with the fixed return is no longer fully watertight. |

|

|

|

| Model CI-8: Corner cubicle with door hung on fixed return: watertight structure |

Hinged to the fixed glass return panel, the door can be opened both ways: to the outside, clearing any radiator, towel-warmer, item of bathroom furniture, etc. on the wall outside the cubicle, and to the inside if the depth of the cubicle allows. Simple to install, this arrangement is fully watertight: the Clip-In Door hinge is screwed to the fixed return screen through a flat section that includes the watertight seal in a second flat section running parallel to the first, but on the outside. This second flat section functions as a full-height clip and conceals the engineered grooves in the underside of the first. Hinged to the fixed glass return panel, the door can be opened both ways: to the outside, clearing any radiator, towel-warmer, item of bathroom furniture, etc. on the wall outside the cubicle, and to the inside if the depth of the cubicle allows. Simple to install, this arrangement is fully watertight: the Clip-In Door hinge is screwed to the fixed return screen through a flat section that includes the watertight seal in a second flat section running parallel to the first, but on the outside. This second flat section functions as a full-height clip and conceals the engineered grooves in the underside of the first. |

|

|

|

Components for installation: |

| CLIP-IN DOOR hinge |

|

The Clip-In Door hinge has a wealth of novel features:

- It is attached with screws along its full height to the edge of a 10 mm-thick glass panel, into a dovetail groove patented by Saint-Gobain Glassolutions.

- Installation is very simple using a wall section and two metal screws.

- It is highly resistant and can withstand extraordinary overloads at the end of the span.

- It is a double-action hinge with some finger pinch protection, opening through +/- 90°.

- With an understated, distinctive design, it discreetly enhances the front of the shower screen without affecting overall transparency and maintaining the appearance of a frameless glass structure.

|

|

|

|

| Flat wall section with seal |

|

The flat wall section plays a number of roles.

For affixing the hinge to the wall, it can help to:

- compensate for out-of-plumb and uneven wall surfaces

- ensure that the installation is watertight, with the addition of sealant in gaps in the tile joints, etc.

- secure the door mounting by screwing the hinge to the section, metal to metal, with the remainder of the section being glued/screwed to the wall.

Where the door is affixed with a hinge to a glass return panel, if a watertight arrangement is required, the seal can be stuck to the flat section that can be inserted between the supporting panel and the hinge. This ensures that it is fully watertight and stops the door from swinging. It is recommended that the hinge be screwed into a facing flat section which, fitted back-to-back with the first, conceals the engineered grooves in the underside of each.

|

|

U section with rebate seal for

wall mounting or free edge of fixed return panel |

|

The rigid U section can be used to:

- affix a 10 mm (or 55.2, for example) fixed screen securely to a wall, or at 90° to another glass panel;

- adjust the position of the glass panel by +/-8 mm;

- hold the section in place against the glass or the glass in place in the section using the special, highly effective rebate seal. In some cases, additional bonding using sealant, MS polymer adhesive or silicone can help secure the installation;

- provide a good alternative to the floor clip which would otherwise be necessary to hold the lower edge of the return glass panel in place;

- provide a flat, smooth supporting surface for a watertight seal on the edge of the door.

|

|

|

L section with rebate seal

for creating a corner joint between two fixed glass panels

The rigid L section can be used to:

- securely attach two fixed 10 mm glass panels (in non-tempered 55.2 glass, for example) to each other create a corner,

with a tolerance of a few degrees in the angle of the corner;

- adjust the position of the glass panel by +/- 2-3 mm;

- hold the section in place against the glass or the glass in place in the section using the special, highly effective rebate seal. In some cases, additional bonding using sealant, MS polymer adhesive or silicone can help secure the installation;

- create a wide range of installations using non-tempered laminated glass, from a five-sided cubicle to a corner enclosure, which may be self-supporting.

It has a simple, sleek, clean design using just metal and glass, and the unobtrusive rebate seal is mounted on the inside. |

|

|

|

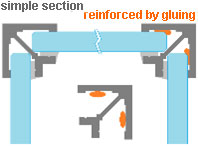

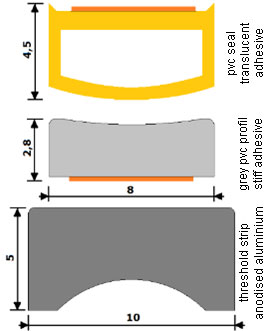

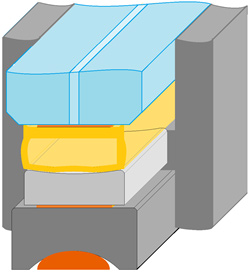

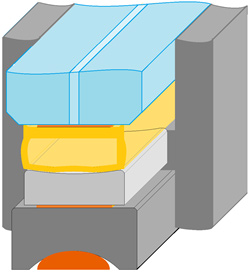

Threshold strip

The threshold strip is an important component in installing an Adler shower cubicle,

- delineating and effectively framing the installation.

- It centres vertical U and L sections and holds them in place.

- It ensures that the base of the shower cubicle is watertight – especially with a tiled shower tray – creating a smooth floor surface and evening out the dips in the tile joints.

- Secure bonding along the full length of the strip using the groove in the underside of the strip ensures durability.

- It avoids drilling into the shower tray, for simple, reliable fitting of the clip that is required for any fixed in-line glass panel. There is no requirement to drill into the shower tray.

- Adler standard watertight sections offer:

- speedy, watertight installation – the rigid PVC section goes right down to the level of the base of the clip, creating a continuous seal along a very smooth supporting surface;

- an alternative arrangement with the threshold strip and seal 79016N (also available in other lengths), which is appropriate for monolithic toughened glass;

- the load is perfectly balanced along the length of the supporting edge, thus protecting the glass. |

|

Shown opposite is the standard combination of the threshold strip bonded to the shower tray, the PVC section and the seal.

Shown below is the threshold strip on its own, bonded to the shower tray to run underneath a door, for example..

|

|

|

|

|

| Capsi support bar with adjusters for L or U rebate sections |

|

Clip-In Door enclosures are designed to be built using 10 mm thick toughened glass. Capsi square stainless steel 20 x 20 mm support bars are recommended to ensure optimum stability: they are unobtrusive and are affixed using screws through the screens that they support. When one end is wall-mounted, for ease of fitting and the ultimate strength of the installation, it is always preferable to screw it into the wall section that is also to be used to affix the hinges, clips, etc |

|

| |

| Profil de chant 10x2 autocollant joint |

|

Adler a conçu un profil aluminium très fin, pré-adhésivé, à coller autour de glaces de 10mm ou 55.2. Ce profil très fin comprend une rainure dans laquelle peut loger un profil joint spécialement développé qui sert à l'indexage en position fermée et à l'étanchéité parfaite d'une porte sur pivot Adlock ou charnière Adler VF.

Le profil est livré en 2m20, joint encollé, et pré-adhésivé au dos prêt à coller sur le chant de la glace. Plusieurs matières de joint sont proposées dans le catalogue ADLER afin de toujours offrir le meilleur compromis entre le prix et la durabilité du joint. |

|

|

|

| Door bottom water deflector section 79043S |

|

Transparent polycarbonate section, self-adhesive along one side and one face. Acrylic adhesive.

Offering full and durable transparency, this section is glued to the base of the door and forces all the water that runs down the door back into the shower tray. Under normal conditions of use, it does not come into contact with the floor or the threshold strip but is fully waterproof. |

|

|

|

| More seals from the ADLER range: |

|

8 x 8 mm solid section in transparent PMMA, bonded using UV adhesive or transparent acrylic biocomposite: it performs the same function as the deflector above, and is recommended for hotels, etc., where these components may be subject to heavy use.

Réf. 79036K |

Adler SAS offers a full range of self-adhesive seals with exceptional properties in terms of mechanical performance, resistance to tearing and atmospheric resistance. Find them in the ADLER catalogue which you can download from our website :

|

|

|

Some ideas for handles: This type of cubicle needs a door handle.

'G-shaped' handle or simple cut-out in the door |

|

This handle is inserted into a semi-circular cut-out in the free edge of the door. Once bonded, it provides effective protection for the machined edge and substantially limits the requirement for lapping after drilling or milling. It offers an attractive, unobtrusive and practical alternative to door knobs and handles.

Better still for a minimalist look, the handle cut-out can simply be lapped.

|

| |

G-shaped handle |

Glass with cut-out |

|

|

|

| Door knobs |

|

|

|

70765U |

69800v & up |

69967B & up |

Adlock round door knob, diameter 30 mm Brushed stainless steel.

Polished finish on request. |

Capsi square door knob 30 x 30 mm. Bronze with high-shine chrome-plated or brushed or gilt stainless steel finish. Single or double door knob. |

Adler round door knob, diameter 30 mm Bronze with high-shine or matte chrome-plated or gilt finish. Single or double door knob. |

|

|

Handles |

|

Families-706-707-708 |

A full range of standard and made-to-order handles in polished or brushed stainless steel, in diameters from 20 to 45 mm.

Mounted horizontally, they make an ideal towel-holder. Options are also available for converting a handle on one side of the door into a handle on the outside and a door knob on the inside (see 70765U), or you could also opt for a pull ring, etc.

|

|

70519B |

Stainless steel handles with a clean design, featuring welded spacers and mounting points for Adlock glass for secure, straightforward fitting.

Single horizontal handle – square, 20 x 20 mm - Length 520 mm - Space between holes 500 mm. |

|

70518A |

Stainless steel handles with a clean design, featuring welded spacers and mounting points for Adlock glass for secure, straightforward fitting.

Single vertical handle – 20 x 20 mm square -

Drilling diameter 10 mm - Height 320 mm - Space between holes 300 mm. |

|

|

With Clip-In Door, where the fixed glass return panel is sufficiently narrow (less than 35 cm wide), this corner and partial alcove installation offers high transparency and simplicity and is fully watertight. On the in-line panel side, the flat section against the wall behind the hinge naturally compensates for uneven or out-of-plumb wall surfaces. It also contains the seal that keeps the hinge watertight. On the fixed return side, the U section glued and screwed to the wall allows for adjustment of the installation by +/-8 mm. The front of the U section is 27 mm wide; the Clip-In Door hinge and associated flat section together measure 23 mm, providing an elegantly balanced installation. Assembly is entirely mechanical, and the only seal strip, in the U section on the return panel, is slimline and near-invisible and is located on the external face of the cubicle, where it cannot be affected by water, soap, etc.

With Clip-In Door, where the fixed glass return panel is sufficiently narrow (less than 35 cm wide), this corner and partial alcove installation offers high transparency and simplicity and is fully watertight. On the in-line panel side, the flat section against the wall behind the hinge naturally compensates for uneven or out-of-plumb wall surfaces. It also contains the seal that keeps the hinge watertight. On the fixed return side, the U section glued and screwed to the wall allows for adjustment of the installation by +/-8 mm. The front of the U section is 27 mm wide; the Clip-In Door hinge and associated flat section together measure 23 mm, providing an elegantly balanced installation. Assembly is entirely mechanical, and the only seal strip, in the U section on the return panel, is slimline and near-invisible and is located on the external face of the cubicle, where it cannot be affected by water, soap, etc. On the fixed return side, the U section recommended for wall mounting helps to compensate for imperfections in the wall surface, providing stability for the installation and simplifying the build process. At the hinge, the flat wall section is essential for secure, easy fitting and a watertight, durable installation. The square 20 x 20 mm support bar provides stability for the in-line panel and maintains the sleek, clean lines of the finish. At floor level, the threshold strips are near invisible, in keeping with the build, and allow the clip that holds the lateral screen in place to be affixed without drilling into the shower tray, with the method of assembly delivering a watertight installation.

On the fixed return side, the U section recommended for wall mounting helps to compensate for imperfections in the wall surface, providing stability for the installation and simplifying the build process. At the hinge, the flat wall section is essential for secure, easy fitting and a watertight, durable installation. The square 20 x 20 mm support bar provides stability for the in-line panel and maintains the sleek, clean lines of the finish. At floor level, the threshold strips are near invisible, in keeping with the build, and allow the clip that holds the lateral screen in place to be affixed without drilling into the shower tray, with the method of assembly delivering a watertight installation.

On the front of this screen, the inset profile of the fixed glass screen provides visual balance for the combination of the Clip-In Door hinge and associated flat wall section. The distinctive mounting of the inset profile on the fixed return enhances the overall impression of transparency and refinement. This method of installation allows for simple adjustments in the width of both cubicle screens by +/- 8 mm.

On the front of this screen, the inset profile of the fixed glass screen provides visual balance for the combination of the Clip-In Door hinge and associated flat wall section. The distinctive mounting of the inset profile on the fixed return enhances the overall impression of transparency and refinement. This method of installation allows for simple adjustments in the width of both cubicle screens by +/- 8 mm.

In this arrangement, the fixed glass panels are all inset, with no screws, making it simple to install and allowing for significant adjustments to size, for example in case of inaccurate measurements. Taken at the scale of a cubicle, all these sections remain slimline and unobtrusive, highlighting the lack of framing on the horizontal edges of the glass panels and making the cubicle look more spaciou

In this arrangement, the fixed glass panels are all inset, with no screws, making it simple to install and allowing for significant adjustments to size, for example in case of inaccurate measurements. Taken at the scale of a cubicle, all these sections remain slimline and unobtrusive, highlighting the lack of framing on the horizontal edges of the glass panels and making the cubicle look more spaciou

This screen showcases the full refinement and technical innovation of the Clip-In Door hinge, which is screwed directly to the glass of the fixed return panel at two separate points. The shower frontage is as transparent as possible: a 5 mm-thick flat section at the wall ensures that the free edge of the door fits perfectly so that the cubicle closes properly and is fully watertight at this point; the Clip-In Door hinge forms a slimline, full-height strip 16 mm wide, typically accounting for less than 2% of the width of the door. Without no supporting sections, the point of abutment with the fixed return is no longer fully watertight.

This screen showcases the full refinement and technical innovation of the Clip-In Door hinge, which is screwed directly to the glass of the fixed return panel at two separate points. The shower frontage is as transparent as possible: a 5 mm-thick flat section at the wall ensures that the free edge of the door fits perfectly so that the cubicle closes properly and is fully watertight at this point; the Clip-In Door hinge forms a slimline, full-height strip 16 mm wide, typically accounting for less than 2% of the width of the door. Without no supporting sections, the point of abutment with the fixed return is no longer fully watertight.

Hinged to the fixed glass return panel, the door can be opened both ways: to the outside, clearing any radiator, towel-warmer, item of bathroom furniture, etc. on the wall outside the cubicle, and to the inside if the depth of the cubicle allows. Simple to install, this arrangement is fully watertight: the Clip-In Door hinge is screwed to the fixed return screen through a flat section that includes the watertight seal in a second flat section running parallel to the first, but on the outside. This second flat section functions as a full-height clip and conceals the engineered grooves in the underside of the first.

Hinged to the fixed glass return panel, the door can be opened both ways: to the outside, clearing any radiator, towel-warmer, item of bathroom furniture, etc. on the wall outside the cubicle, and to the inside if the depth of the cubicle allows. Simple to install, this arrangement is fully watertight: the Clip-In Door hinge is screwed to the fixed return screen through a flat section that includes the watertight seal in a second flat section running parallel to the first, but on the outside. This second flat section functions as a full-height clip and conceals the engineered grooves in the underside of the first.